The journey of tinplate packaging began in 1819, when William Underwood established the first tin can factory in Boston, USA. His method involved cutting tinplate sheets to size, hand-welding them into cylindrical shapes, sealing both ends with round plates, and adding a small opening for filling. Initially, the focus was purely on preserving food quality, but with time, designs were printed on the surface—turning the tin can into both a functional and decorative product that could attract consumer attention.

Tinplate (electrolytic tin-coated steel) refers to a thin, low-carbon steel sheet (carbon content below 0.13%) coated with an extremely thin layer of tin (0.10–0.15 μm). Its layered structure includes:

| Layer | Function |

|---|---|

| Steel Base | Structural support and durability |

| Tin-Iron Alloy Layer | Improves bonding between steel and tin |

| Pure Tin Layer | Corrosion resistance |

| Tin Oxide Film | Extra protective barrier |

| Oil Film | Enhances processing and handling |

This multi-layered design allows tinplate to be used for food cans, edible oil containers, pharmaceutical tins, construction materials, household appliances, signage, and toys.

Depending on the contents, an internal coating is often required to prevent corrosion of the container wall and protect the product from contamination—essential for long-term storage. For example:

Candy tins: Coating prevents rust during edge rolling and enhances visual appeal.

Food cans: Coatings must resist corrosion, adhere well, be flexible, non-toxic, odorless, and compliant with food safety standards, while also withstanding processes such as high-frequency resistance welding and sterilization at 121°C without discoloration or gloss loss.

Common coating types: Phenolic resin, epoxy-phenolic resin, acrylic resin, and aluminum powder coatings—chosen based on content type and required thickness.

Since printing is typically done before can forming—which involves bending, stretching, welding, flanging, and sealing—a base coat is applied to ensure ink adhesion and prevent cracking or peeling.

Requirements for Base Coats:

High transparency with minimal yellowing

Smooth leveling, heat curing, and flexibility

Strong affinity with ink and adhesion to tinplate

White cadine is thicker and more opaque than white ink, offering better gloss, fullness, and surface smoothness. It contains film-forming agents, pigments, rust inhibitors, and solvents.

| Feature | White Coating (White Cadine) | White Ink |

|---|---|---|

| Thickness | 3–4× thicker | Thin |

| Whiteness & Fullness | High | Moderate |

| Gloss & Smoothness | Excellent | Standard |

| Resistance to Varnish Corrosion | Strong | Less resistant |

| Yellowing Resistance | Strong after multiple bakes | Less resistant |

Plate making for tinplate differs from other substrates due to its non-absorbent surface and hardness:

Dot Shape Selection – Circular or diamond dots help avoid tonal jumps in mid-tones, unlike square dots.

Pre-Forming Allowances – Space must be left for welding seams to avoid design misalignment after forming.

No Printing on Seam Areas – Especially for spray cans, seam edges must be free of graphics or color for welding purposes.

Tinplate printing uses offset lithography due to its smooth, hard surface. However, inks must meet special requirements:

| Ink Property | Reason for Importance |

|---|---|

| Heat Resistance | Withstands 150°C curing and up to 220°C during welding |

| Solvent Resistance | Prevents smudging during varnishing |

| Steam Resistance | Maintains integrity during sterilization |

| Processability | Survives bending, punching, and sealing |

| UV & Weather Resistance | Avoids fading during storage |

| Heavy Metal-Free | Complies with US/EU/Japan export standards |

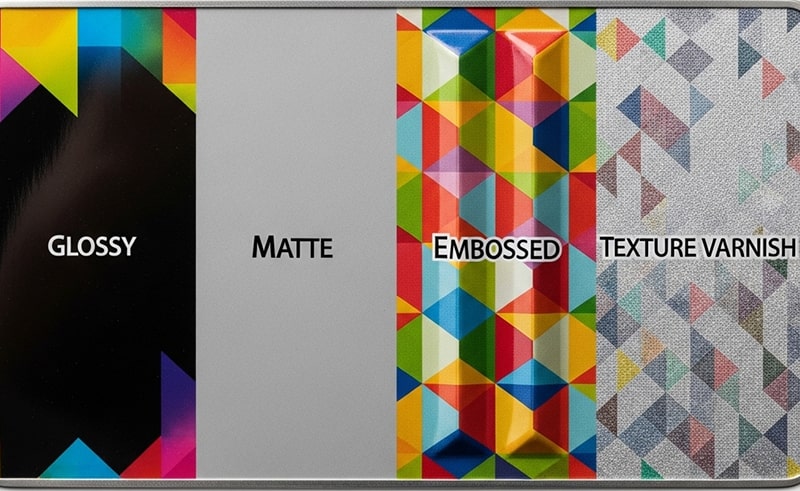

After printing, tinplate is coated with varnish to enhance gloss, scratch resistance, and corrosion protection.

Types of Varnishes:

Gloss – High shine, traditional appeal

Matte – Paper-like, elegant texture

Wrinkle – 3D crystal-like patterns for artistic value

Pearlescent – Iridescent finish for luxury branding

Varnish Selection Factors: Resistance to discoloration, compatibility with base coat, flexibility, and durability.

The drying process involves:

Heating Zone – Raises temperature to set level

Holding Zone – Maintains peak temperature for curing

Cooling Zone – Prevents surface damage during stacking

Key Insight: Under-curing leads to weak adhesion, while over-curing causes brittleness and yellowing. Monitoring oven temperature curves is essential.

From a production standpoint, custom tinplate printing is a fusion of engineering and artistry. Modern buyers demand not just protection but brand differentiation, regulatory compliance, and eco-conscious materials.

Our factory has implemented:

BPA-free coatings for global compliance

Energy-efficient curing systems for cost savings

Short-run digital printing for seasonal and promotional packaging

These measures allow us to deliver flexible, high-quality tinplate solutions that align with both sustainability and branding goals.

| Benefit | Business Impact |

|---|---|

| Product Freshness | Extends shelf life |

| Premium Look | Boosts perceived value |

| Custom Designs | Differentiate in the market |

| Sustainability | Attracts eco-conscious buyers |

| Compliance | Opens access to EU/US/Japan markets |

Looking for a custom tinplate printing solution that blends durability, compliance, and brand appeal?

📩 Contact us today to explore tailored options for your food, beverage, or premium gift packaging needs.

💬 Which tinplate printing effect—gloss, matte, wrinkle, or pearlescent—do you think creates the strongest shelf impact in your industry? Share your thoughts below!